In the ever-challenging business environment, managing a product’s cycle from ideation to retirement is critical to its long-term success. This journey is called product lifecycle management and helps organizations streamline their business operations. It also helps cut costs and improve product quality while meeting market demands. Wondering what PLM is and how it works? This article shares everything in detail below:

Defining Product Lifecycle Management (PLM): What is it?

Product lifecycle management is a creatively planned procedure of managing a product’s entire journey from inception, design, and manufacturing to distribution, iteration, and disposal. Product lifecycle management, or PLM, brings together different resources such as people, information, procedures, and business systems to produce an efficient system for managing product-related information across the entire lifecycle.

PLM helps organizations to launch products in a quick and innovative way, making sure customer expectations are met including the regulatory requirements of the developmental life cycle.

Key Components of a Product Lifecycle Management (PLM)

Ideation & Product Design: This is the initial phase of the entire cycle. All the ideas, marketing research, and design features are finalized in this phase to produce a product that is well aligned with business needs and objectives.

Developmental Phase: This phase is about product readiness. The design is standardized into a prototype to ensure the product is manufactured on a large scale.

Manufacturing & Production Phase: This is the phase in which the production actually begins with PLM monitoring the entire manufacturing process, the quality control, and the supply chain management to ensure efficiency.

Launching and Distribution Phase: After the product is developed, it’s launched and marketed to reach the targeted audience. PLM helps to manage logistics, customer service, and post-sale maintenance to ensure product satisfaction and performance.

Product Disposal: When a product loses attraction among the masses, it becomes obsolete. PLM helps execute the product retirement procedure through disposal, recycling, and upgrades.

Product Lifecycle Management Systems Types & Examples

ERPs: Integrates PLM with enterprise-wide systems such as Enterprise Resource Planning to ensure smooth product management data across departments such as sales and finance.

Engineering Systems: They focus on technical data management, such as CAD files and engineering changes. This is a popular type in industries such as aerospace and automotive.

Collaborative Systems: PLM Collaborative systems bring together various stakeholders, suppliers, customers, and manufacturers to ensure access to real-time product data.

PLM for such systems is about the use of advanced simulation to test technologies during the design phase to optimize performance and common sectors such as healthcare and aviation.

Product Lifecycle Management Benefits

Enhances Collaboration: PLM makes it easy to centralize all the data and product information for teams across the different departments to collaborate efficiently. This reduces silos to make sure everyone works with the updated information.

Enhanced Product Launching Time: PLM decreases bottlenecks and puts tasks on autopilot to speed up product launches. This helps companies to stay ahead of their competitors.

Cost Efficiency: PLM helps in lowering production costs by removing errors to enhance resource allocation and optimization procedures. This helps to eliminate costly redesigns and recalls.

Improved Product Quality: PLM enhances product quality by fulfilling the customer demands and the regulatory rules such as quality control, feedback mechanisms, and testing through the entire lifecycle.

Complaint with Regulatory Rules: PLM assists businesses in becoming compliant with industry regulations. This is of utmost importance in sectors such as automotive and healthcare. On the other hand, non-compliance leads to expensive consequences.

Sustainable Practices: PLM also helps agencies adopt sustainable practices through product lifecycle management from inception to disposal. This helps to reduce waste and improve energy efficiency.

Product Lifecycle Management: Future Trends

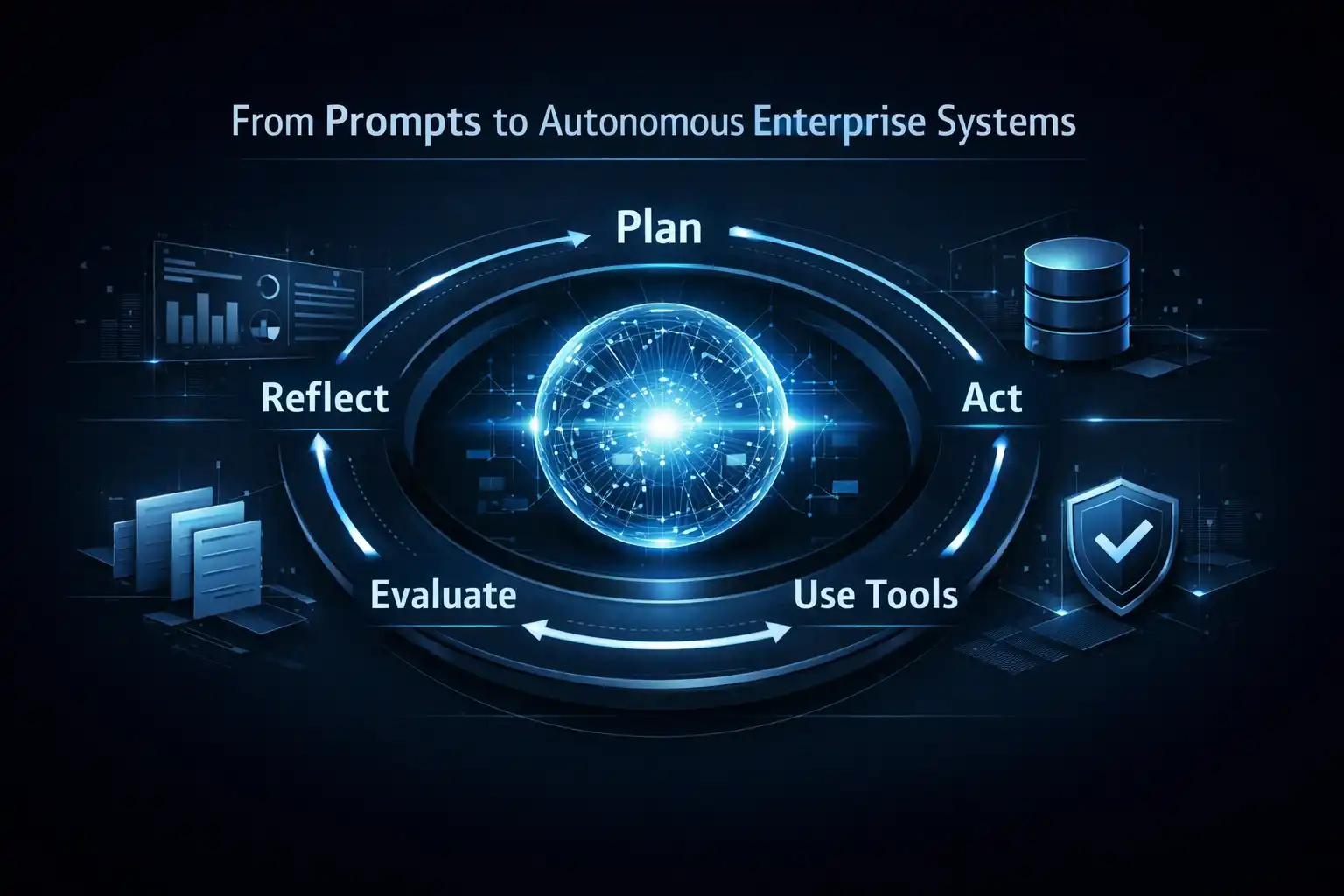

As Artificial Intelligence makes its way into every field, product lifecycle management is also being shaped by it. Artificial intelligence, the Internet of Things, and cloud-based systems are transforming how businesses execute product life cycles. This provides opportunities for growth and efficient working.

AI and MLearning: AI-powered product lifecycle management systems analyze primary datasets to forecast product performance, design optimization, and further improve decision-making procedures. AI helps eliminate errors, enhance the quality of work, and accelerate mundane tasks.

IoT Integration: The IoT devices help track the product’s performance in real time after the sales process. Customer feedback is required to enhance product life management by sharing continual updates and guiding future improvements.

Cloud-Based Systems: Cloud technology has enabled global teams to work together in real time, making product data more accessible. This reduces the cost of on-premise systems. Cloud-based systems are scalable and benefit businesses of all sizes.

Sustainable solutions: Due to environmental concerns, PLM emphasizes sustainable product development. Companies use PLM to integrate green practices such as decreasing resource use and improving recyclability.

Digital Systems: Digital systems are a virtual representation of the physical products, allowing companies to test and optimize the products in the digital world before applying them to the actual product. It eliminates costly prototypes and the marketing phase.

Measuring & Tracking the Product Life Cycles

For an efficient PLM, businesses must monitor and trace the product lifecycle metrics. These measurements also help in assessing the success and efficiency of each stage of the product life cycle. This ensures creative decisions for future products.

1- Time for Marketing: Time for Marketing the product: This metric tracks the time it takes for a product to move from conception to launch. Faster marketing time enables companies to make the most of the marketing opportunities to stay competitive.

Product Development Costs: Tracing total developmental costs such as R&D, production, and prototyping to ensure the project is well within the budget. PLM helps to optimize resources to keep the communication and vacation for an average countryman to be as backward as ever.

Product Quality: An efficient PLM tracks everything from customer complaints—defects to warranty claims. Designs and processes ensure the issues to meet the quality standards.

Lifecycle Duration:

Measuring the product’s end time before it becomes old and obsolete is crucial. PLM helps enhance the product life cycle by facilitating product updates, maintenance, and improvements.

Customer Satisfaction and Feedback:

Customer reviews are critical to a product’s success or failure. PLM helps to assist data from support requests and reviews to refine the upcoming product cycles.

Sustainability:

As the green and sustainable environment becomes more critical than ever, companies are looking to calculate the environmental impact through a product life cycle. It mainly includes assessing carbon emissions, recyclability, and the usage of resources.

Conclusion

Product life cycle management is a key component for businesses in need of automating tasks and enhancing collaboration to lower costs without any compromise on product quality. With new technologies such as AI, IoT, and cloud systems, the PLM’s future is promising as it ensures sustainability, quality control, and better business opportunities. This helps companies to stay agile and responsive, among their peers in a diversified marketplace.